Natural diamonds are formed over billions of years under conditions of extreme pressure and temperature deep underground. Synthetic forms can be obtained much faster, but they usually still require intensive crushing for several weeks.

The new method, based on a mixture of liquid metals, allows you to get an artificial diamond in a matter of minutes, without the need for giant pressing.

Although high temperatures were still required, in the region of 1025°C or 1877°F, a solid diamond film was formed in 150 minutes and at a pressure of 1 atm (or standard atmosphere). This is equivalent to the pressure we experience at sea level, and tens of thousands of times less than the pressure normally required.

The team developing the innovative approach, led by researchers from the Institute of Basic Sciences in South Korea, are confident that this process can be scaled up to fundamentally change the production of synthetic diamonds.

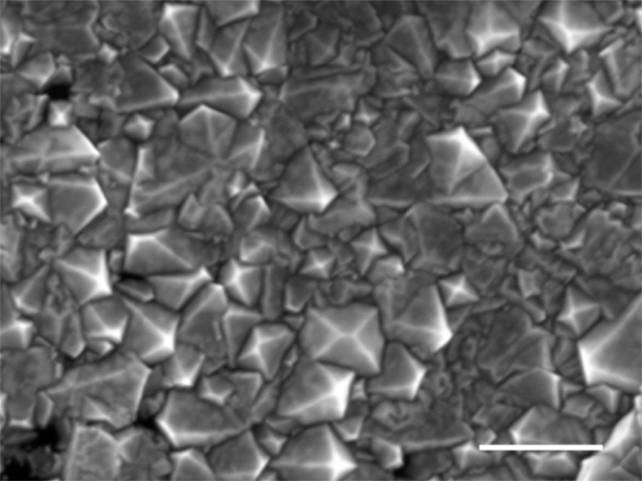

Scanning electron micrograph of a diamond film grown in liquid metal. (Gong et al., Nature, 2024)

Dissolving carbon in liquid metal to make diamond is nothing new. For example, General Electric developed this process half a century ago using molten iron sulfide.

But these processes still required a pressure of 5-6 gigapascals and a diamond "seed" to which the carbon could cling.

"We have discovered a method of growing diamonds at a pressure of 1 atm and a moderate temperature using a liquid metal alloy," the researchers write in their published article.

The pressure reduction was achieved using a carefully mixed mixture of liquid metals: gallium, iron, nickel and silicon. A special vacuum system was built inside the graphite shell to very quickly heat and then cool the metal under the influence of a combination of methane and hydrogen.

Under these conditions, the carbon atoms from the methane spread throughout the molten metal, acting as seeds for the diamonds. After only 15 minutes, small fragments of diamond crystals were squeezed out of the liquid metal just below the surface, and after two and a half hours of exposure, a solid diamond film was formed.

Although the concentration of carbon that forms the crystals has decreased to a depth of only a few hundred nanometers, the researchers expect that the process can be improved with some adjustments.

"We hypothesize that simple modifications could allow diamond to be grown over a very large area by using a larger surface or interface, configuring the heating elements to achieve a much larger potential growth area, and distributing the carbon in the diamond growth area in some novel ways," the researchers write.

These modifications take time, and research into the process is still in its very early stages, but the authors of the new study believe it has great potential – and that other liquid metals could be used to achieve similar or even better results.

The process currently used to create most of the synthetic diamonds used in a variety of industrial processes, electronics and even quantum computers takes several days and requires much more pressure. If this new technology fulfills its potential, creating diamonds will become much faster and easier.

"The general approach of using liquid metals can accelerate and promote diamond growth on various surfaces, and possibly facilitate diamond growth on small diamond (seed) particles," the researchers write.

120

120